Uncoated Recycled Paperboard

Strong, Sustainable and Suitable URB for Global Demand

Globally, Sonoco operates 23 paper mills in 13 countries with a total annual capacity of 2.1 million tons. Our infrastructure and capacity allow us to act swiftly across the world to meet demand for uncoated recycled paperboard (URB).

Global Paper Supplier

Sonoco operates paper mills in 13 different countries, providing recycled paperboard for packaging and other applications to customers around the globe. Our paper footprint includes brands like PaperTech and Skjern.

- US and Canada

- Latin America

- Europe

- Asia

Investing in URB

Sonoco has invested $125 million to strengthen our uncoated recycled paperboard mill system in the U.S. and Canada. The majority of the URB investment – known as Project Horizon – includes transforming the company’s Hartsville, S.C., corrugated medium machine into a state-of-the-art URB machine with annual production capacity of approximately 180,000 tons.

We look forward to bringing our customers a wide variety of high-value URB grades.

Responsible Sourcing, Impactful URB Products

All but two of our 23 global paperboard mills use 100% recycled fibers in their production. Sonoco is committed to responsible use of natural resources through responsible sourcing, recycling, and use of recycled fiber in our paper-based packaging. Sonoco's mills throughout Europe, the U.S., Canada, Brazil, China, and Mexico (Atizapan), are certified to one or more fiber certification programs. These are: the Forest Stewardship Council® (FSC®), Sustainable Forest Initiative® (SFI®) and the Program for the Endorsement of Forest Certification® (PEFC®) Chain of Custody and Due Diligence System Standards.

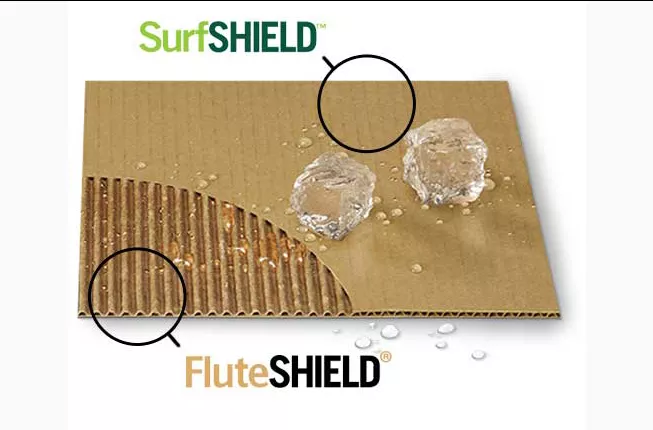

Custom Coating and Lamination Solutions

Cascades Sonoco’s extensive range of laminates and coatings allow for virtually limitless customization. Combinations of multiple functional barrier platforms enable customers to tailor orders to meet complex and extreme conditions, such as significant changes in temperature or environment, global transportation and varying country regulations.

Connect with Sonoco

Learn more about our uncoated recycled paperboard packaging offerings. We’re eager to discuss how we can help you meet your customers’ needs and your business goals.